FR4/G10 Sheet

Industrial Manufacturing & Precision Machinery

Used for producing gears, bearings, and mold insulation boards. It features high strength and wear resistance, extending equipment service life.

Construction & Infrastructure

As a lightweight, high-strength material, it is used for structural reinforcement and sound and thermal insulation panels, enhancing project durability.

Raw Materials

Epoxy Resin: An organic polymer compound containing two or more epoxy groups. These active groups react with curing agents to form a three-dimensional network polymer that is insoluble and infusible.

Reinforcement Material: Commonly non-alkali glass fiber cloth, sometimes high-purity cellulose paper. Glass fiber cloth improves mechanical strength and dimensional stability.

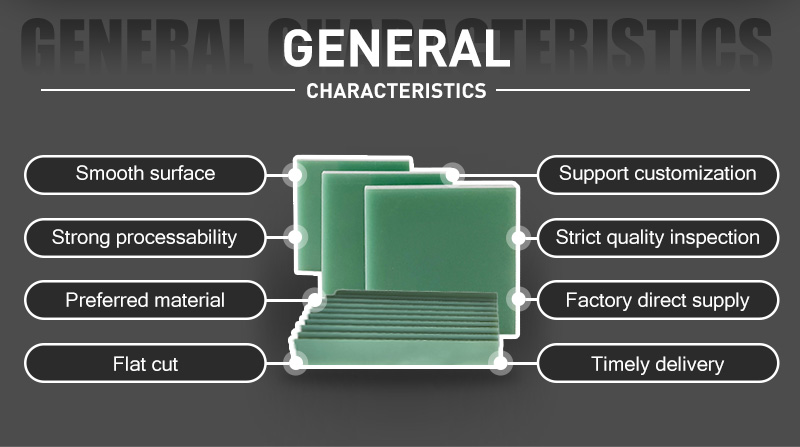

Key Characteristics

Strong Adhesion: Epoxy resin contains polar hydroxyl and ether bonds, giving it strong adhesion to various materials. Its low curing shrinkage and minimal internal stress help enhance bonding strength.

Low Shrinkage: The curing reaction involves no volatile by-products, resulting in shrinkage of less than 2%.

Excellent Mechanical Properties: Cured epoxy resin has good mechanical strength and can withstand high pressure and impact.

Good Electrical Properties: High dielectric strength, surface leakage resistance, and arc resistance make it an excellent insulating material.

Strong Chemical Resistance: Offers excellent resistance to acids, alkalis, and solvents. Selecting specific resins and curing agents can enhance chemical stability.

Outstanding Dimensional Stability: The combination of various properties ensures long-term size and structural stability.

Mildew Resistance: The cured epoxy system resists most types of mold and can be used in harsh tropical conditions.

Specifications & Appearance

Thickness: Typically ranges from 0.5 mm to 100 mm

Standard Size: Usually 1000 mm × 2000 mm

Color: Commonly yellow

Application Fields

Aerospace: Used in aircraft, rockets, and satellites due to its high strength, corrosion resistance, low friction, and lightweight.

Electronics: A common base material for circuit boards with excellent insulation, mechanical strength, and high-temperature resistance, ideal for high-density circuits and miniature components.

Transportation: Used in tunnel linings for highways, subways, and railways to prevent water penetration and avoid geological hazards.

Petroleum Industry: Used as insulation material, liners, pump components, and other mechanical parts due to its wear resistance, corrosion resistance, and high strength.

Machinability

Epoxy sheets are easy to process and can be cut, drilled, punched, and milled into parts of various shapes and sizes to suit different applications. In electronics manufacturing, for example, epoxy sheets can be processed into specific insulating brackets, spacers, and other parts.